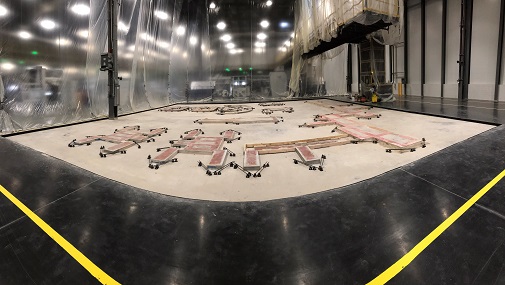

Continental Tire’s manufacturing facility was designed to use thin concrete overlays surrounding uniquely shaped pedestals to achieve the right elevation to house critical pieces of manufacturing equipment. Experience showed that traditionally reinforced concrete using welded wire reinforcement would not be suitable to control cracking within these thin concrete slabs, so they needed a design that could offer a high degree of protection against plastic and drying shrinkage cracks.

The Challenge

All concrete slabs are susceptible to cracks, but this application was particularly prone to cracking, and required optimum protection to ensure the performance of the base plates and pedestals. The FRC topping slab was just 3” thick, which made it a tremendous a challenge for crack reduction. In addition, the concrete pedestals were uniquely shaped, which resulted in areas of high stress in the topping slabs where cracks tend to occur.

The Solution

The engineering firm of Burns Cooley Dennis (BCD) consulted with GCP and together they came up with a solution: Focus on the fundamental cause of drying shrinkage cracking and control the cracks when they occur. By working closely with the ready-mix producer, Delta Industries, to arrive at an optimized mixture proportion, BCD was able to optimize the performance of this mixture by adding ECLIPSE® Floor 200 and lower drying shrinkage to an acceptable value. In addition, BCD worked with GCP engineers and scientists to determine the appropriate amount of STRUX® 90/40 macro synthetic fibers to ensure that any cracks that occurred were within an acceptable level of performance.

ECLIPSE® Floor 200 acts chemically to dramatically reduce the primary internal forces that causes shrinkage and curling. By reducing the surface tension of the water in the pores of the concrete, drying shrinkage can be reduced as much as 50% over a control mixture. STRUX® 90/40 macro synthetic fibers are made from a blend of polymers and are equally distributed throughout the concrete matrix to impact long-term crack control properties. This impacts toughness as well as impact and fatigue resistance while reducing plastic shrinkage cracking.

Unlike welded wire mesh, with macro synthetic fibers there is no risk of corrosion, and none of the job site risks of using welded wire or steel reinforcement. STRUX® 90/40 macro synthetic fibers provide all the benefits of microfibers, in addition to increased durability, flexural toughness, and resistance to impact and abrasion.

In particular to this project, STRUX® 90/40 fibers were able to mitigate the effects of plastic and drying shrinkage cracking in a relatively thin, heavily loaded, uniquely shaped, unjointed, and bonded overlay, which by all-rights should have not only cracked, but been subject to large crack width openings.

STRUX® macro fibers advance the field of fiber reinforced concrete, giving designers more flexibility in the range of forms, enabling contractors to offer crack protection with less time, labor, and materials.

“This concrete placement presented several challenges to our team because it was a thin bonded topping slab with no crack control joints,” said Burns Cooley Dennis, Inc. Senior Concrete Materials Engineer Robert Varner, P.E. “In addition, this topping slab would be constructed adjacent to hundreds of inside and reentry corners built into the existing slab. We were concerned with shrinkage cracking, curling, and stress cracks at corners. To address these concerns, we incorporate a shrinkage reducing admixture into the concrete and macro synthetic fibers from GCP Applied Technologies to reduce curling and to hold cracks tight. To date, we have a crack-free topping slab, and plans are being made to use this same mixture to construct additional topping slabs within this facility.”

gcpat.sg | For technical information: asia.enq@gcpat.com

GCP Applied Technologies Inc., 2325 Lakeview Parkway, Alpharetta, GA 30009, USA

GCP (Singapore) Pte. Ltd, 25 Tanjong Penjuru, Singapore 609024.

This document is only current as of the last updated date stated below and is valid only for use in Singapore. It is important that you always refer to the currently available information at the URL below to provide the most current product information at the time of use. Additional literature such as Contractor Manuals, Technical Bulletins, Detail Drawings and detailing recommendations and other relevant documents are also available on www.gcpat.sg. Information found on other websites must not be relied upon, as they may not be up-to-date or applicable to the conditions in your location and we do not accept any responsibility for their content. If there are any conflicts or if you need more information, please contact GCP Customer Service.

Last Updated: 2025-05-15

https://gcpat.sg/en-gb/about/project-profiles/synthetic-macro-fibers-improve-durability